Steel fabrication has always been about strength. But behind every beam, plate and sheet is work that demands far more than brute force. Steel is heavy, awkward and unforgiving. It flexes when lifted, shifts when rotated, and punishes poor control. Day after day, operators are expected to move it safely, precisely and repeatedly.

That is where smart lifting changes the conversation.

Rather than asking people to absorb the weight of steel through their bodies, industrial manipulators remove the physical load while preserving control. The result is safer handling, better accuracy and workflows that feel sustainable rather than exhausting. It is a shift that aligns not only with productivity goals, but also with recognised ergonomic and manual handling guidance such as NOHSC:2005 (1990).

The real problem with steel is not just the weight

Ask anyone on a fabrication floor and they will tell you the same thing. Steel handling is not only about how heavy a load is. It is about how unpredictable it can be.

Large plates flex. Thin sheets behave differently to thick ones. Long beams demand balance through every movement. When these tasks are done manually, operators compensate with their bodies. Over time, that compensation shows up as fatigue, strain and injury. It also shows up in slower cycle times, damaged material and costly rework.

Modern safety frameworks recognise this reality. Where high-risk manual handling exists, the expectation is not better technique alone, but mechanical assistance that reduces exposure at the source.

What smart lifting actually looks like on the floor

Smart lifting does not replace skill. It removes unnecessary physical effort so skill can be applied properly.

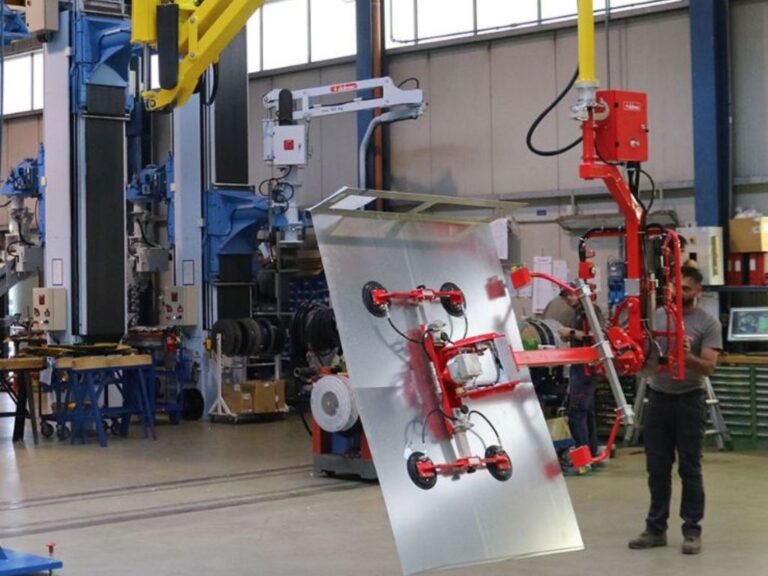

Industrial manipulators use pneumatic balancing to neutralise the weight of steel components. Operators guide the load with light, controlled movement rather than force. Lifting, rotating and positioning become smooth and predictable actions. This is why industrial manipulators for precise and safe material handling are increasingly adopted in environments where control matters as much as strength.

Instead of two people wrestling with a steel plate, a single operator can position it accurately. Instead of fatigue dictating the pace of work, consistency is maintained across the entire shift.

Safety improves when effort is removed, not when people try harder

One of the biggest misconceptions in industrial environments is that safety improves through awareness alone. In reality, safety improves when physical strain is designed out of the task.

By removing load weight from the operator, industrial manipulators significantly reduce stress on shoulders, backs and wrists. This directly supports ergonomic risk management and aligns with established manual handling principles reflected in standards such as NOHSC:2005 (1990).

This approach also delivers measurable commercial value. Reduced injuries mean less downtime, fewer lost-time incidents and improved retention of skilled workers. Ergonomic material handling becomes an investment rather than an expense because it addresses the root causes of risk and inefficiency at the same time

Precision and productivity are not trade-offs

In steel fabrication, accuracy is not optional. A few millimetres can mean the difference between a clean fit and expensive rework.

Smart lifting supports precision by giving operators controlled movement across multiple axes. Steel components can be aligned, rotated and placed without sudden shifts or overcorrection. This improves quality while also speeding up the process. When effort is reduced, motion becomes more efficient and cycle times shorten naturally.

In many operations, tasks that once required two people can be completed by a single operator in a fraction of the time, without increasing risk or fatigue.

Designed around real fabrication workflows

No two fabrication floors are identical. Steel handling varies by size, thickness, shape and stage of production. Effective lifting systems must adapt to that reality.

Dalmec manipulators are engineered around real workflows, not generic assumptions. Solutions such as the Dalmec Partner EQUO are designed to handle heavy and off-centre steel loads while maintaining balance and intuitive control throughout the lift.

This adaptability allows lifting systems to integrate seamlessly into existing processes, supporting productivity without disrupting established workflows.

For teams planning or reviewing steel handling processes, the Steel Fabrication interactive resource page brings together application-specific images and videos in a format that can be explored visually. Users can scroll through real steel fabrication images and watch videos to better understand how different lifting solutions are applied across fabrication workflows before moving into detailed design discussions.

Supporting people as well as production

When the physical strain of steel handling is reduced, the benefits extend beyond injury statistics. Operators experience less fatigue. Confidence improves. Skilled workers remain productive for longer and demanding roles become more sustainable.

Smart lifting systems support compliance, but more importantly, they support people. They allow experience and skill to be applied consistently without being limited by physical wear.

A smarter way forward for steel handling

Stealing the weight from steel is not about automation for its own sake. It is about creating safer, more precise and more sustainable fabrication environments.

By combining ergonomic design, controlled movement and application-specific engineering, industrial manipulators change how steel handling feels on the floor. The work flows better. Risk is reduced. Results improve.

To explore how smart lifting could improve safety and efficiency in your steel fabrication operation, visit our solutions page and speak with our team.