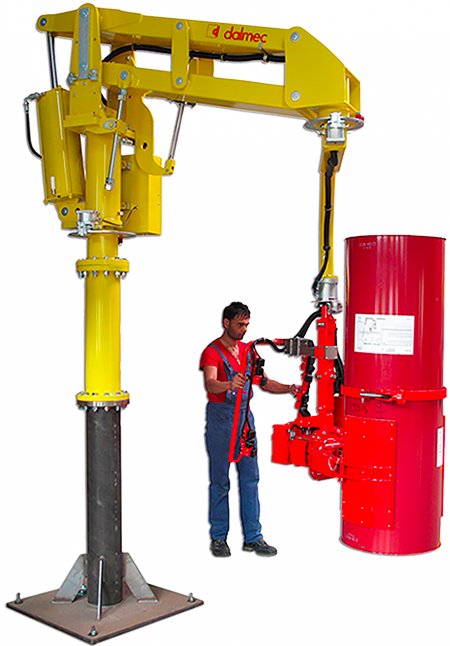

Powerful industrial manipulators, lift assist devices, and material handlers designed to meet the highest safety standards. Dalmec engineers will work closely with you to custom build to the exact specifications for your job.

Every sector faces material handling problems, but Dalmec can help.

From food and pharmaceutical to textile and packaging, Dalmec’s lift assist devices and pneumatic manipulators perfectly integrate into a company’s infrastructure, satisfying handling needs and slashing costs while improving an organization’s structure.

The Global Leader in Industrial Manipulators and Lift Assist Devices

Powerful industrial manipulators, lift assist devices, and material handlers designed to meet the highest safety standards. Dalmec engineers will work closely with you to custom build to the exact specifications for your job.

Solutions for your industry

Every sector faces material handling issues, but Dalmec can assist. From food and pharmaceuticals to textiles and packaging, Dalmec’s lift assist devices and pneumatic manipulators seamlessly integrate into a company’s infrastructure, addressing handling requirements and reducing costs while enhancing an organization’s structure.

Proven Solutions to your Material Handling Problems

It’s highly likely that Dalmec has expertly addressed your material handling challenges in various parts of the world. With over five decades of experience and a dedication to innovation, we’ve consistently provided top-notch solutions that guarantee the smooth flow of materials in a multitude of industries.

The Global Leader in Industrial Manipulators and Lift Assist Devices

Powerful industrial manipulators, lift assist devices, and material handlers designed to meet the highest safety standards. Dalmec engineers will work closely with you to custom build to the exact specifications for your job.

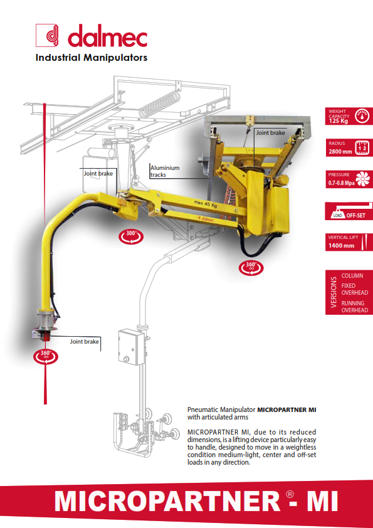

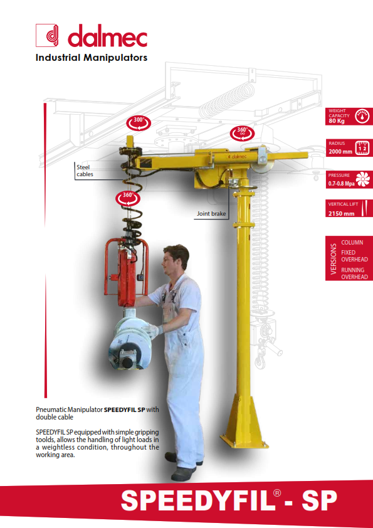

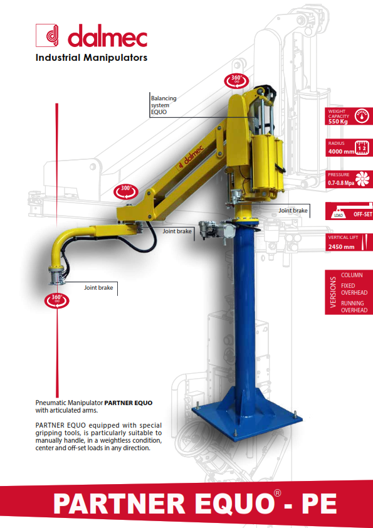

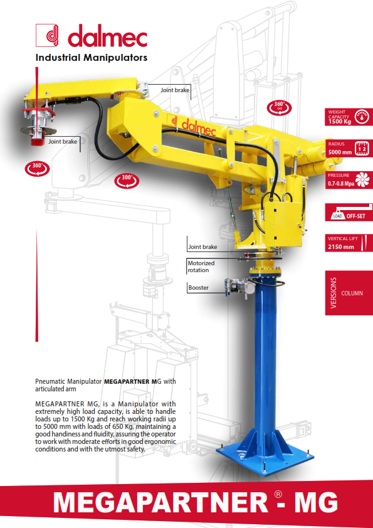

Discover our MANIPULATORS

- 11 Models designed to satisfy all handling requirements in every industrial sector.

- DALMEC Industrial Manipulators allow the ergonomic, safe and effective handling of any product.

- We are able to lift every kind of product weighing from 6 up to 1500 kg using compressed-air only.

Manual handling of loads

- NIOSH method for the Lifting Index in the Manual material handling

- Snook and Ciriello method for the activities such as pushing, pulling and transport loads on floor surfaces.

These rules are applied to the activities involving the manual handling of loads with risks to the operators of injuries to the back.

The workplace must be fitted with proper means to reduce the risks deriving from the manual handling of loads.

When it is not possible to avoid the manual handling of the loads (lifting, pushing, drawing, transport), the employer must provide the worker with suitable means to reduce the risks deriving from these operations.

Limit values for the lifting of loads:

- Kg 25 Adult males

- Kg 20 Adult females

- Kg 20 Teenage males

- Kg 15 Teenage females

There are coefficients of reduction of the limit values, which consider:

- Height of the hands from the ground at the beginning of lifting

- Vertical distance of the load from the beginning to the end of the lifting cycle

- Distance between the load and the body during lifting

- Rotation of the bust for angular displacement of the load

- Possibility of taking the load.

The installation of mechanical arms also for weights lower than 30 kg, enables the operator to:

- Work quicker

- Notably reduce physical fatigue

- Eliminate the risk for the back

- Non-skilled personnel to carry out manual handling

- Reduce the risk of injuries.

Our Products

Benefits of using Dalmec manipulators

- Enhance Productivity and Cost Efficiency

Transform a task that previously required two or three individuals into a one-person operation.

Achieve a more sustainable workload for operators.

- Elevate Safety, Job Satisfaction, and Morale

Minimise work-related fatigue and stress.

Simplify or promote job rotation, encouraging a safer and more satisfying work environment.

Benefits of using Armtec manipulators

- Increase Productivity / Reduce Costs

Turn a two or three-person job into a one-person job.

Greater sustainable work level from operator.

- Improve Safety, Job Satisfaction and Morale

Reduce work fatigue and stress

Eliminate or facilitate job rotation

Precision, safety and efficiency – delivered.

Two critical components of successful manufacturing are precise and safe movement.

Dalmec’s manipulators and material handling devices meet strict safety standards and are built with the protection of the user in mind, ensuring high-quality, long-lasting machines that are customized to meet customers’ unique needs.

“We are committed to sustainability – for every Dalmec machine sale, we plant a tree.”