Choosing the right material handling partner can dramatically improve safety and productivity in your operation. By asking the right questions up front, you’ll ensure any lifting solutions you invest in actually solve your challenges and boost your bottom Line.

For operations managers and plant engineers, the start of a new year is a critical time for strategic planning. You’re likely evaluating workflows, pinpointing bottlenecks, and looking for ways to improve safety and production efficiency. If heavy, awkward, or fragile loads are part of daily life on your factory floor, you might be considering new safe material handling methods or lifting solutions (like industrial manipulators) to protect workers and streamline work. But selecting the right material handling partner is just as important as choosing the right equipment. There are plenty of off-the-shelf hoists and lifters out there, but a generic gadget rarely delivers true improvement. Real gains come from partnering with a provider who understands your unique environment and can tailor a solution to fit.

Below, we outline seven key questions to ask any potential partner. These go beyond simple pricing and lead times – they dig into the engineering depth, safety features, and long-term support a provider will bring to your facility.

1. Will the Solution Be Customised for Your Product’s Needs?

Many suppliers take a one-size-fits-all approach – they’ll ask the weight of your load, check a chart, and recommend a standard hoist or balancer. The truth is, weight is often the easiest variable in material handling. The real challenges are your product’s shape, size, surface texture, fragility, and the exact movements required to lift and place it. If a provider only offers a cookie-cutter device, you risk an ill-fitting solution that doesn’t truly solve your problem.

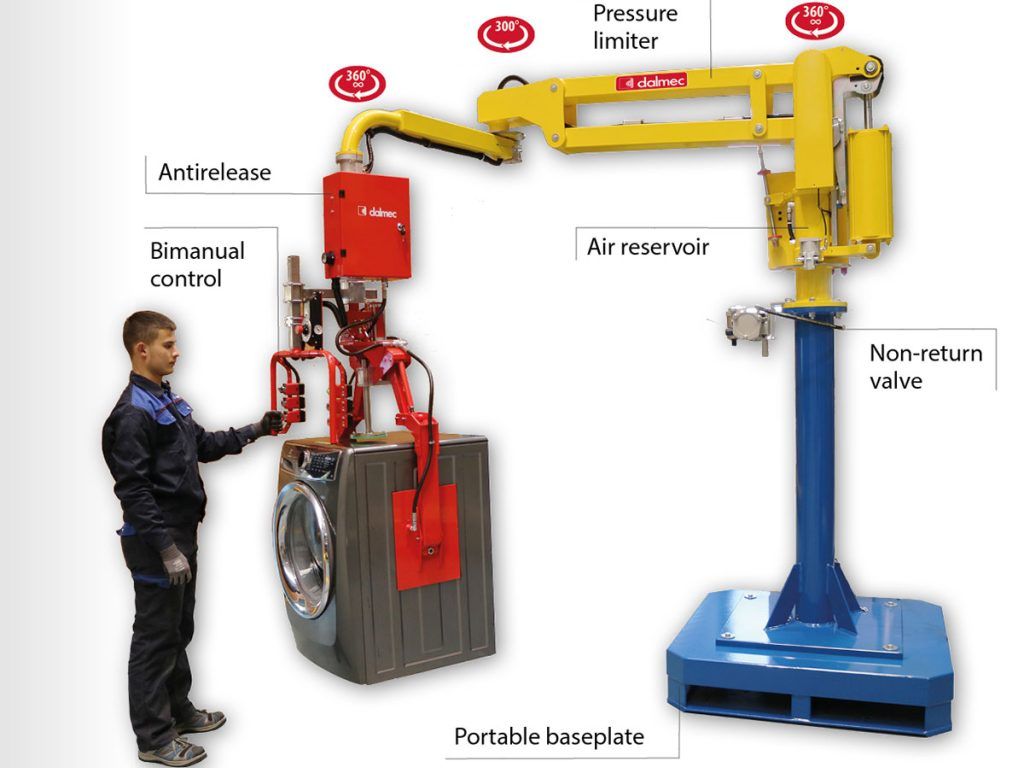

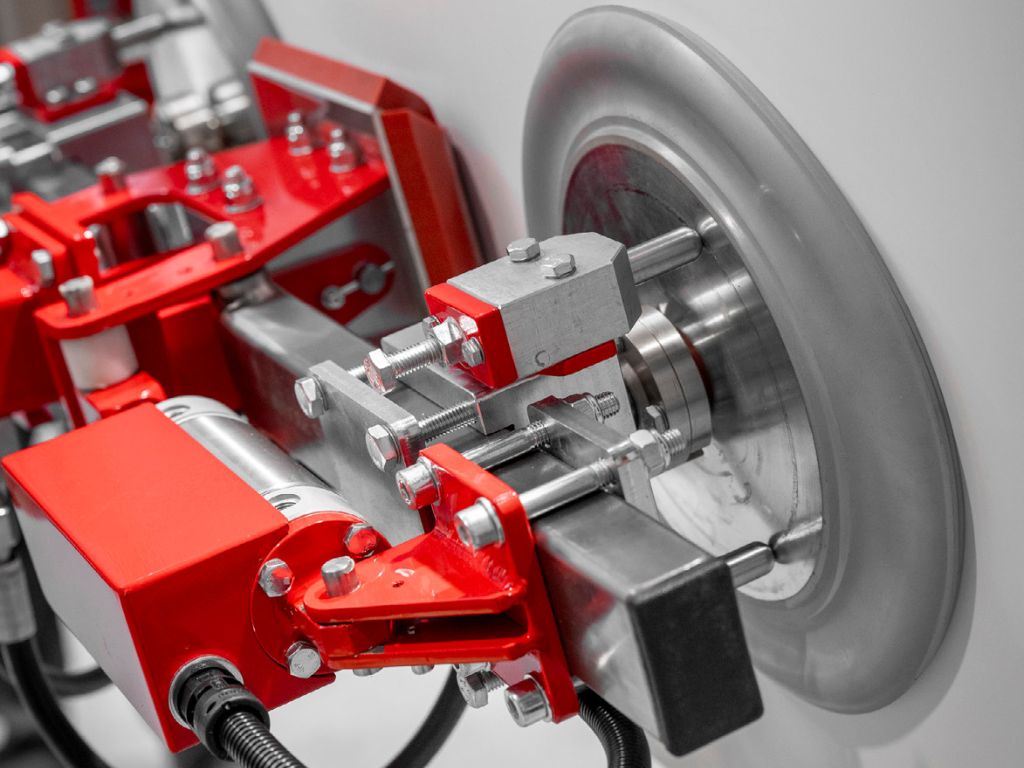

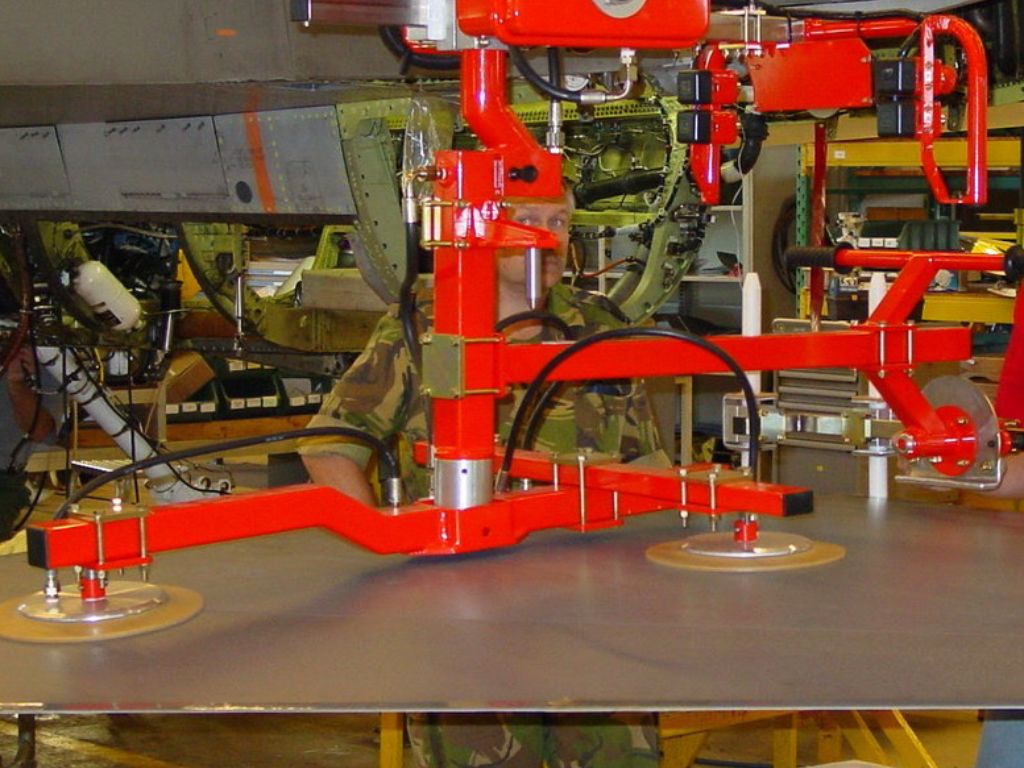

Ask if they can design tooling specific to your item. A true partner looks not just at what you’re lifting, but how it needs to be lifted. Can they create custom end-effectors – the gripping attachments – tailored to your product? For example, lifting a large roll of film by its core or handling a thin-walled stainless steel drum without denting it requires specialised tooling. A basic hook or clamp won’t cut it for these scenarios.

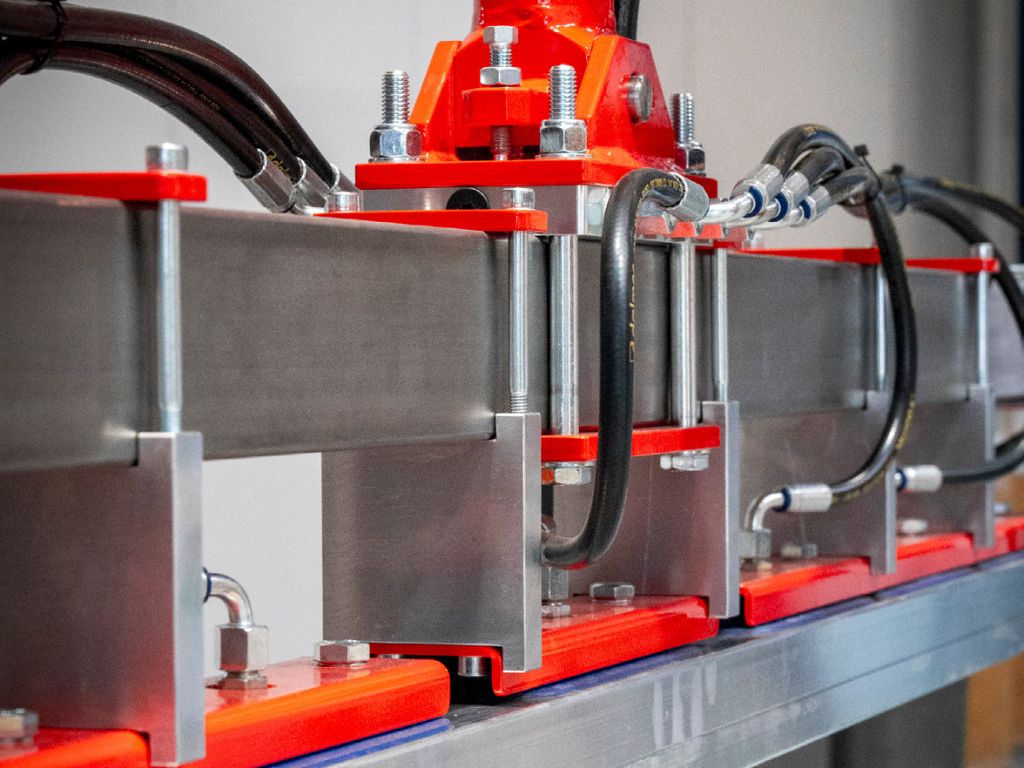

- Look for deep customisation capabilities: The partner should be able to engineer bespoke gripping tools (e.g. vacuum suction cups, internal expansion mandrels, custom clamps) designed for your product’s exact dimensions and material.

- Ask about complex manoeuvres: If your process involves flipping a load from vertical to horizontal, reaching over obstructions, or rotating an item to slot it onto a shelf, the system must handle shifts in the load’s centre of mass without becoming unstable. Ensure the provider can accommodate these unique lifting motions in their design.

When a supplier builds the solution around your product – instead of forcing your product to fit their standard device – you’ll see gentler handling, less product damage, and faster cycle times.

2. How Will It Integrate into Your Workspace and Workflow?

No factory or warehouse is a blank canvas waiting for new equipment. Your facility likely has a crowded floor plan with existing machinery, conveyor lines, structural columns, narrow aisles, and perhaps low ceilings. A lifting device might sound great on paper but prove impractical if it doesn’t physically fit or if it obstructs operations. So, it’s critical to consider how a new manipulator or lift will work within your current layout.

A reliable partner will view their equipment as part of your overall workflow – essentially the bridge between workstations – rather than a standalone island. Ask each vendor how they address spatial constraints and what mounting options they offer. For instance, if a supplier only provides floor-mounted systems, they won’t be much help if you need to keep aisles clear for forklift traffic or if floor space is at a premium.

- Verify mounting flexibility: Can the system be floor-mounted, column-mounted, or ceiling-mounted? Top providers offer options like overhead rail systems or jib cranes that utilise ceiling space to cover large work areas without blocking the floor. If you have narrow aisles or multi-station coverage needs, an overhead running rail manipulator might be ideal.

- Check vertical adaptability: If your facility has low ceilings or obstacles (like HVAC ducts, pipes, or mezzanines), a standard tall post or gantry may not fit. In such cases, can the partner engineer a low-profile, rigid-arm manipulator that reaches into tight spaces or under obstructions? The solution should adapt to your building constraints – for example, a rigid arm that can dip under a low overhead or a compact mast that fits beneath the ceiling – where a typical cable hoist would fail.

By ensuring the equipment is designed for your workspace – not just for the load – you avoid costly surprises at installation. The right device will slot into your operations smoothly, acting as connective tissue that streamlines material flow instead of a bulky addition that gets in the way.

3. Does It Empower Your Operators (Not Replace Them)?

In the rush toward automation, it’s easy to assume a fully robotic solution is best for material handling. But in many complex assembly or packing tasks, the human operator is indispensable. There’s no substitute for human judgment when, say, aligning a part during assembly, dealing with inconsistent packaging, or spotting quality issues on the fly. The ideal material handling solution gives your workers the strength and support of a machine while preserving their skill and control.

When evaluating a partner, discuss how their technology interacts with the user. You’re not looking to make your workers redundant – you want to augment their capabilities. The manipulator or lifting device should feel like an extension of the operator’s arm, not a clunky robot that isolates them from the task. If the operator feels disconnected or wrestling with controls, productivity and safety can suffer.

- Prioritise intuitive controls: Look for equipment that is naturally easy to use. The best manipulators allow the operator to guide and position a load with minimal effort – often through a simple joystick, handle, or pendant that responds instantly to their touch. In practice, the device should move with the operator’s motions. Avoid systems that require punching in commands or slowly inching via buttons for every little movement; those will frustrate workers and slow down the process.

- Opt for smooth, reliable operation: Many modern industrial manipulators use pneumatic logic or fluid power for a very responsive feel, rather than overly complex electronics. Pneumatic lift-assist devices, for example, can provide a “floating” effect where the load moves fluidly and stops exactly when and where the operator intends. This kind of design tends to feel more natural and is often preferred for precision handling tasks, since the operator can make fine adjustments effortlessly.

Your goal is a safer, more efficient workflow with your team at the helm. A solution that empowers operators will improve morale and engagement, because workers feel safer and more capable rather than threatened by automation. In short: technology should elevate your people, not eliminate them.

4. What Safety Features and Fail-Safes Are Built In?

Safety is non-negotiable when you’re lifting heavy items like steel components, glass panels, or chemical drums. With loads potentially weighing hundreds of kilograms, even a brief lapse or equipment fault can have serious consequences. That’s why you should probe deeply into the safety mechanisms of any proposed solution. It’s not enough for a provider to say, “Yes, it’s safe” – ask them exactly what happens if something goes wrong.

Some important “what if” questions include: What if the power or air supply to the lift is suddenly cut? What if an operator accidentally hits the release or stop button at the wrong time? A reputable partner will have engineered answers to these scenarios – beyond just warning labels and emergency stop buttons.

For instance, consider a common hazard: if a load slips or is accidentally dropped mid-lift, a basic cable-balancer device might snap upward violently when the weight is released, creating a dangerous whip effect. A better-designed manipulator will have fail-safes to prevent that. It might lock in place or gently drift to a neutral position to avoid slingshotting and protect the operator. Other safety features to look for:

- Redundant holding mechanisms: Does the gripper have dual valves or locks that engage if primary power fails, so the load doesn’t drop? Vacuum lifters, for example, should have reserve vacuum tanks or check valves to maintain suction long enough to safely lower the item if power goes out.

- Controlled movement limits: Quality systems often include travel limiters, torque limiters, or sensors that prevent sudden or dangerous motions. For example, if an operator tries to lift a load beyond the rated capacity, the system might refuse to operate or alert the user, rather than simply failing under overload. Similarly, some devices have brakes that automatically engage if a component malfunctions.

Be sure the partner can clearly explain every safety feature and worst-case scenario response. Safe material handling isn’t just about productivity – it’s about making sure every lift is incident-free. Knowing the equipment has robust fail-safes will give you peace of mind that you’re not introducing new risks to your staff.

5. How Do They Verify the Solution Will Work Before Delivery?

There’s a big difference between a CAD drawing on a computer and a machine operating on your factory floor. One of the smartest questions you can ask a potential partner is about their testing and validation process. How will they prove that the solution works for your specific application before it arrives at your door?

A trustworthy provider should offer a rigorous factory acceptance test (FAT) as part of the project. In plain terms, this means they assemble the entire manipulator or lifting system at their facility and test it using your actual product (or an exact mock-up of it) prior to shipment. This step is your insurance policy that all the engineering calculations and promises actually hold up in real-world conditions.

Consider what a thorough validation looks like:

- They should run the machine through multiple cycles with your load: lifting it, moving it through the required motions (tilting, rotating, extending, etc.), and setting it down just as it would on your line. This checks balance, gripping strength, range of motion, and control smoothness.

- Any issues observed during testing can be fixed before shipping. The last thing you want is a surprise on installation day – finding out the arm can’t reach the pallet on the floor, or a clamp doesn’t hold a slippery part securely. By catching and addressing issues in the factory test, the partner ensures that when the equipment arrives on site, it’s ready to go to work immediately with minimal Adjustments.

Don’t hesitate to request a video or even a live demonstration of the test if you can’t be there in person. Seeing your prospective lifting solution successfully handle your products is incredibly reassuring. It also shows that the partner is confident and transparent about their design. In the end, this validation step saves time and money, because your team won’t waste weeks tinkering with a “finished” system that should have been perfected before it shipped.

6. Do They Have Experience in Your Industry?

Material handling needs vary dramatically across industries. A solution that’s perfect for a heavy automotive assembly line might be completely wrong for a food processing plant or a pharmaceutical warehouse. Beyond just general engineering, your partner should understand the specific regulations, standards, and challenges of your industry. This expertise ensures the equipment will be compliant and effective in your environment from day one.

For example, if you operate in a chemical manufacturing or paint facility, you may have flammable atmospheres where any spark could be disastrous. In such cases, you’ll need explosion-proof or ATEX-rated manipulators that won’t ignite fumes.

Alternatively, in food and beverage production, hygiene is paramount – equipment may need to be made of stainless steel, with smooth surfaces and wash-down capability, to meet strict sanitation standards. In pharma or medical device manufacturing, cleanroom-friendly designs (e.g. no particle-shedding materials, special lubricants, easy-to-sanitize surfaces) could be required.

Here are a few industry-specific points to discuss with a potential partner:

- Hazardous environment compliance: Can they provide systems built for hazardous locations, such as intrinsically safe controls or pneumatic designs that meet standards for explosive atmospheres? If you need an ATEX-compliant or IECEx-rated manipulator, make sure the vendor has done that kind of build before. It’s not the sort of thing you want them attempting for the first time with your order.

- Hygienic and food-grade design: If cleanliness and corrosion resistance are concerns, confirm that the provider offers food-grade lifting equipment – for instance, using 304 or 316 stainless steel construction, FDA-approved or food-safe seals and lubricants, and designs with minimal crevices so they won’t harbor bacteria. Ask if they’ve worked with companies in your sector (dairy, meat processing, pharmaceuticals, etc.) and what adjustments they make for those Environments.

Don’t accept vague assurances like “Sure, we can handle that.” Look for examples or case studies of similar projects in your field. A partner who has solved challenges for businesses like yours will be better prepared to deliver a seamless solution. Plus, they’ll already speak the language of your industry’s safety codes and operational needs, which saves you time in getting them up to speed.

7. What Support and Training Do They Provide After Installation?

The relationship with a material handling partner shouldn’t end the day the equipment is delivered and paid for. In fact, that’s when the real partnership begins. Your new manipulator or lifting device is a long-term investment – a workhorse that will be used every day for years on end. To keep it running reliably (and to get the most value from it), you’ll need ongoing support, maintenance, and training. So, ask potential partners what happens after the sale.

Start with operator training. Even the best tool can underperform if your staff aren’t comfortable using it. Does the vendor offer on-site training to teach your team how to safely and efficiently operate the new equipment? A hands-on training session during installation can greatly shorten the learning curve and boost worker confidence. You want your operators to feel at ease with the technology, rather than intimidated or left to figure it out themselves.

Next, discuss maintenance and spare parts. All machines require upkeep – seals wear out, hoses need replacement, and so on. Find out if the partner has a local service presence in Australia or a support team you can call quickly. Do they stock critical spare parts and can they ship them rapidly? You don’t want to be stuck waiting weeks for a component to arrive from overseas while your production is halted. Ideally, the provider can dispatch common replacement parts overnight and offer technical help promptly to troubleshoot any issues.

- Accessible technical support: Ask how you will get support if something goes wrong. Will you have a direct line to a knowledgeable technician or engineer who understands your specific system? Beware of companies that funnel you into a generic call centre – you’ll waste valuable time explaining your setup to someone who might not have the expertise to help. A good partner will have a dedicated support line or rep for their industrial clients, so you can get answers and parts quickly when needed.

- Long-term maintenance plan: Inquire about recommended maintenance schedules and the expected lifespan of the equipment. A well-engineered manipulator, when properly maintained, can serve you for decades. The partner should be able to outline what servicing is required (e.g. annual inspections, replacement of wear parts every few years) to keep it in top condition. This not only maximises safety but also ensures you get a strong return on investment over the life of the machine.

In essence, you’re not just buying a piece of equipment – you’re entering a long-term partnership. Make sure the company will stand by their product with the support you need to keep downtime to a minimum. Knowing you have training, expert advice on call, and readily available parts will let you operate with confidence for years to co

Final Thoughts

Choosing the right material handling partner is a decision that will impact your operation’s efficiency, safety, and even employee morale for years into the future. By posing the seven essential questions above, you shift the conversation from simply “What does the product cost?” to “What value does the provider bring to my business?”

The goal is to find a partner who will build a solution, not just sell you a product. The right partner will have the engineering expertise to tackle your unique lifting challenges, the commitment to safety to protect your people, and the relevant industry experience to ensure everything is compliant and appropriate for your environment. As you refine your operational plans for the year ahead, take the time to vet potential providers on these points – it can make all the difference in your productivity and results moving forward.

Ready to take the next step towards safer, more efficient material handling in your facility? Contact our team today to discuss your needs and discover how the right industrial manipulator solution can transform your operations. We’re here to help you lift smarter, work safer, and achieve more every day.