Australia’s manufacturing sector is gaining momentum. Policy initiatives such as Future Made in Australia and a renewed focus on local supply chains are driving growth across food, chemicals, defence, and industrial manufacturing.

But growth brings pressure. Manufacturers are facing labour shortages, rising WHS costs, and the challenge of increasing output without increasing injury risk or workforce fatigue.

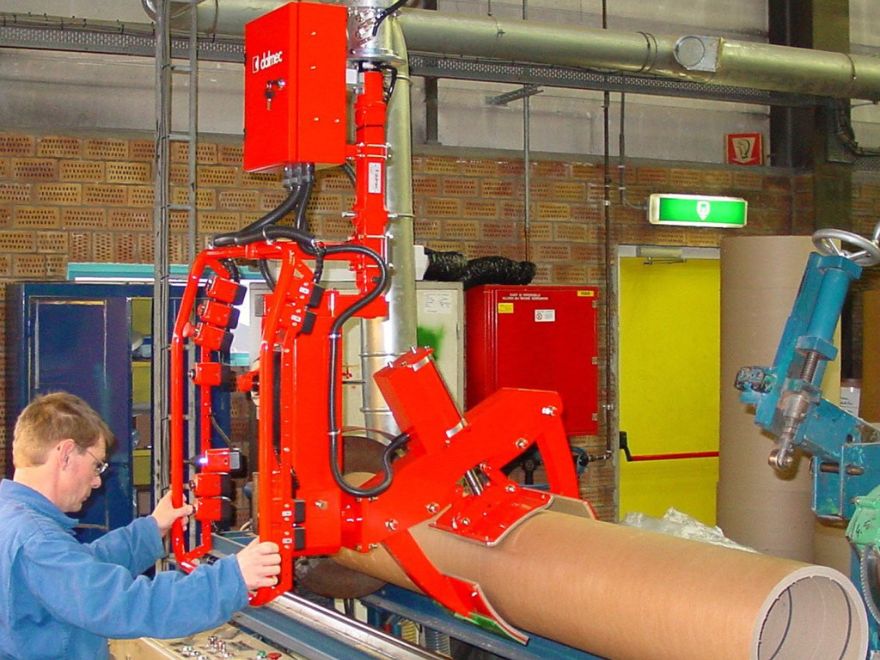

One solution gaining traction across Australian factory floors is the use of industrial manipulators. These precision lifting systems are helping businesses lift safer, work more efficiently, and scale operations without adding headcount.

The Hidden Cost of Manual Lifting

Manual handling remains the leading cause of serious workplace injuries in Australia. According to Safe Work Australia, musculoskeletal disorders account for the majority of compensation claims in manufacturing environments.

The impact is felt well beyond the injured worker:

- Lost time incidents and disrupted shifts

- Increased workers compensation and insurance costs

- Missed production targets

- Reduced workforce confidence and morale

Even loads under 20 kg can cause long term injury when lifted repeatedly, awkwardly, or without proper mechanical assistance. Often, a single incident is enough to disrupt operations for weeks.

The most effective way to reduce this risk is to remove the physical strain from the lift itself.

What Is an Industrial Manipulator and Why Use One

Industrial manipulators are pneumatic lift assist systems that allow a single operator to lift, rotate, tilt, and position heavy or fragile items with precise control and minimal physical effort.

Unlike forklifts or fixed automation, manipulators are designed to integrate directly into existing workflows. They are ideal for confined spaces, irregular loads, and tasks where accuracy and operator control are critical.

They are commonly used across:

- Food and packaging lines handling drums, buckets, and cartons

- Chemical and pharmaceutical facilities managing hazardous containers

- Sheet metal and fabrication environments handling panels and assemblies

- Defence and aerospace maintenance tasks requiring precision handling

Systems can be floor mounted, column mounted, or overhead mounted, and are custom engineered to suit your layout, payload, and workflow.These solutions are used across a wide range of industries, from food and packaging through to defence and heavy manufacturing.

How Manipulators Support Manufacturing Growth

Australian manufacturers are under pressure to grow without overloading their workforce. Manual lifting slows workflows, increases fatigue, and adds long term injury risk.

Industrial manipulators help by:

- Reducing manual handling injuries

- Converting two person lifts into safe one person tasks

- Improving WHS compliance and audit outcomes

- Maintaining consistent throughput in tight or complex work areas

A common outcome reported by Australian manufacturers is improved safety paired with measurable productivity gains.

“After installing a Dalmec manipulator, fatigue complaints dropped to zero and we reclaimed hours of production time each week.”

Production Manager, Australian packaging facility

Lift Safer, Waste Less, Operate Smarter

Manual handling is not only a safety risk. It is also a productivity bottleneck. Dropped items, damaged product, spills, and operator fatigue all erode margins.

With pneumatic Dalmec manipulators, operators are no longer lifting weight. They are guiding the load.

This delivers:

- Smooth, damage free handling

- Controlled rotation and positioning for assembly or filling

- Fewer stoppages and more predictable output

Many systems operate entirely on compressed air, with no electrics and minimal maintenance, making them reliable and well suited to demanding industrial environments.

VLM and Dalmec Supporting Australian Industry

VLM supplies Dalmec industrial manipulators across Australia and New Zealand, tailoring each system to the real world needs of local manufacturers.

Our approach includes:

- On site assessment of lifting risks and workflows

- Custom tooling and gripper design

- Installation, training, and long term support

With over 650 systems installed locally, many operating for decades, Dalmec manipulators are proven to deliver long service life, safety, and consistent performance in Australian conditions.

Is It Time to Rethink Manual Lifting

If your team is still manually lifting 16 kg or more, the risk is already present. The question is not if an injury will occur, but when.

Whether you are preparing for growth or stabilising your workforce, addressing manual handling early protects both people and productivity.

If you would like to explore safer lifting options, speak with our team to see how an industrial manipulator could be tailored to your operation.

Let’s build safer, smarter, and more sustainable production floors, one lift at a time.